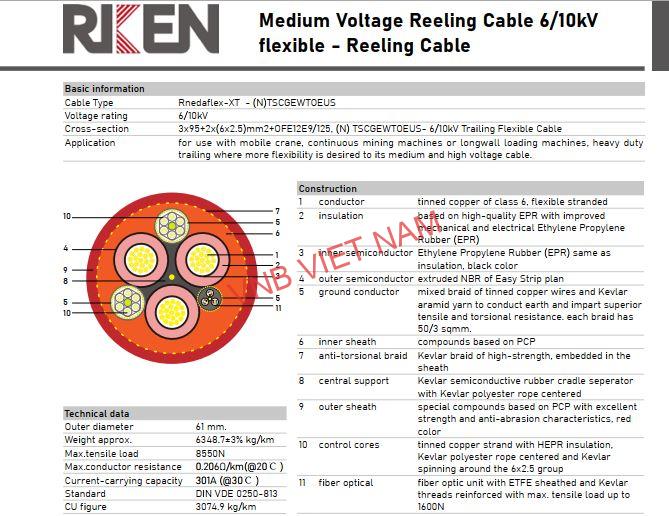

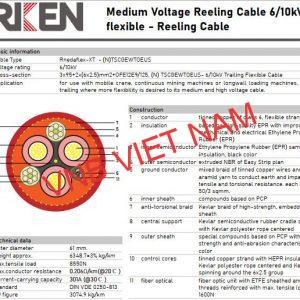

Medium Voltage Reeling Cable 3×95+2x(6×2.5)mm2, 6/10kV

Liên Hệ

Cable Type Rnedaflex-XT – (N)TSCGEWTOEUS

Brand: Riken Huatong/China – Voltage rating 6/10kV

Cross-section 3×95+2x(6×2.5)mm2+OFE12E9/125, (N) TSCGEWTOEUS- 6/10kV Trailing Flexible Cable

Application for use with mobile crane, continuous mining machines or longwall loading machines, heavy duty

trailing where more flexibility is desired to its medium and high voltage cable.

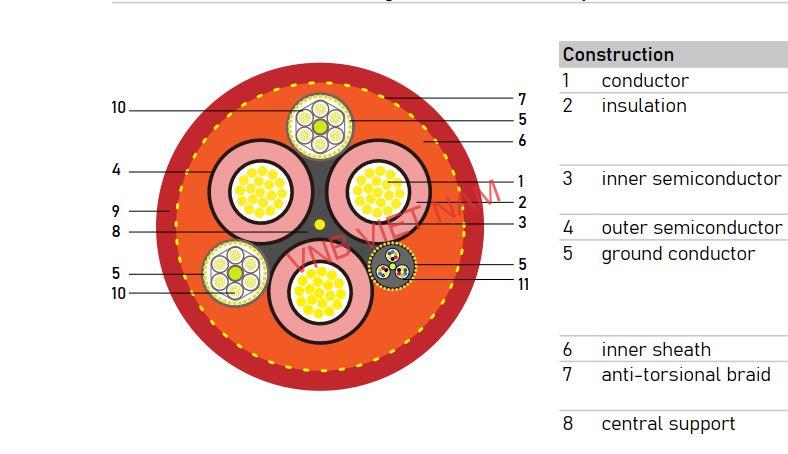

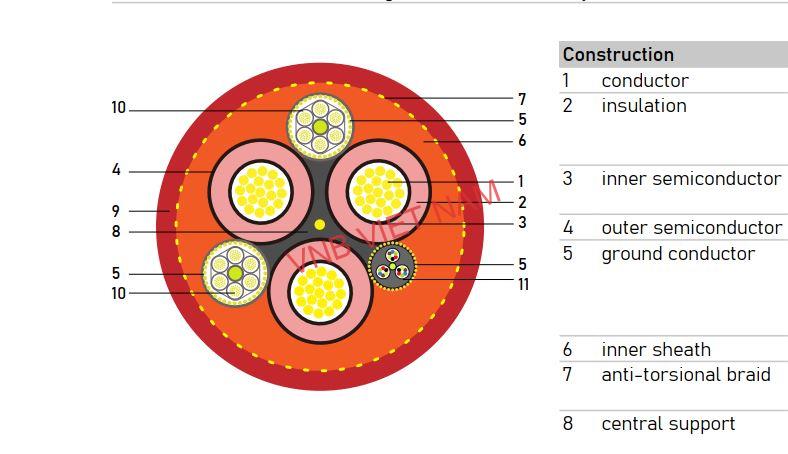

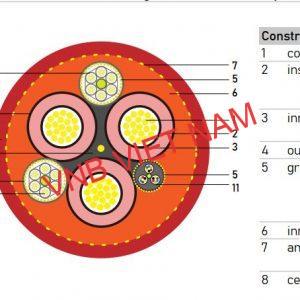

Construction

1. conductor tinned copper of class 6, flexible stranded.

2. insulation based on high-quality EPR with improved

mechanical and electrical Ethylene Propylene.

Rubber (EPR.)

3. inner semiconductor Ethylene Propylene Rubber (EPR) same as

insulation, black color.

4. outer semiconductor extruded NBR of Easy Strip plan

5. Ground conductor mixed braid of tinned copper wires and Kevlar

aramid yarn to conduct earth and impart superior.

Tensile and torsional resistance. each braid has.

50/3 sqmm.

6. Inner sheath compounds based on PCP.

7. Anti-torsional braid Kevlar braid of high-strength, embedded in the

sheath.

8. central support Kevlar semiconductive rubber cradle seperator

with Kevlar polyester rope centered.

9. outer sheath special compounds based on PCP with excellent

strength and anti-abrasion characteristics, red color.

10. control cores tinned copper strand with HEPR insulation,

Kevlar polyester rope centered and Kevlar

spinning around the 6×2.5 group.

11. fiber optical fiber optic unit with ETFE sheathed and Kevlar

threads reinforced with max. tensile load up to

1600N.

Technical data

Outer diameter: 61 mm.

Weight approx.: 6348.7±3% kg/km

Max.tensile load: 8550N

Max.conductor resistance: 0.206Ω/km(@20℃ )

Current-carrying capacity: 301A (@30℃ )

Standard: DIN VDE 0250-813

CU figure: 3074.9 kg/km

Electrical parameters

Rated voltage: 6/10 kV

Max. permissible operating voltage AC : 6.9/12 kV

Max. permissible operating voltage DC: 9/18 kV

AC Test Voltage: 17 kV (5min.)

Thermal parameters

| Max. permissible temperature at conductor Max. short circuit temperature of the conductor Ambient temperature for fixed installation Ambient temperature in fully flexible operation |

90 °C 250 °C min -50 °C ;max +80 °C min -40 °C ;max +80 °C |

Chemical parameters

Resistance to fire similar to IEC 60332-1

Water resistance suitable for permanent use in water up to 50 meter diving depth. special

water such as rain should be upon request.